Let’s learn about

Green Shield is a special Barrier coated paper (Polymer) developed by Hankuk Paper, Which has been manufactured by using a different method compared to other Barrier coating methods hence does not require PE coating and it can be reused in paper material

Naming of Green Shield

Green Shield is a name that signifiles the Environment (Green), Pritection (Shield) and environmentally beneficial coating.

BI of Green Shield

Color Green is used as the main color so it can intuitively be understood to be an eco-friendly product and the leaf graphic is expressed to further emphasize the environmental aspect.

Will  really be “decomposed”?

really be “decomposed”?

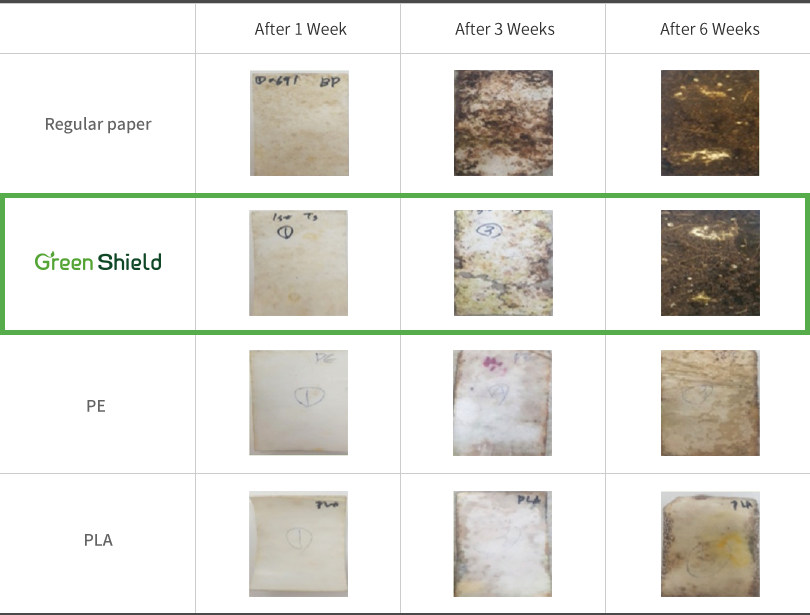

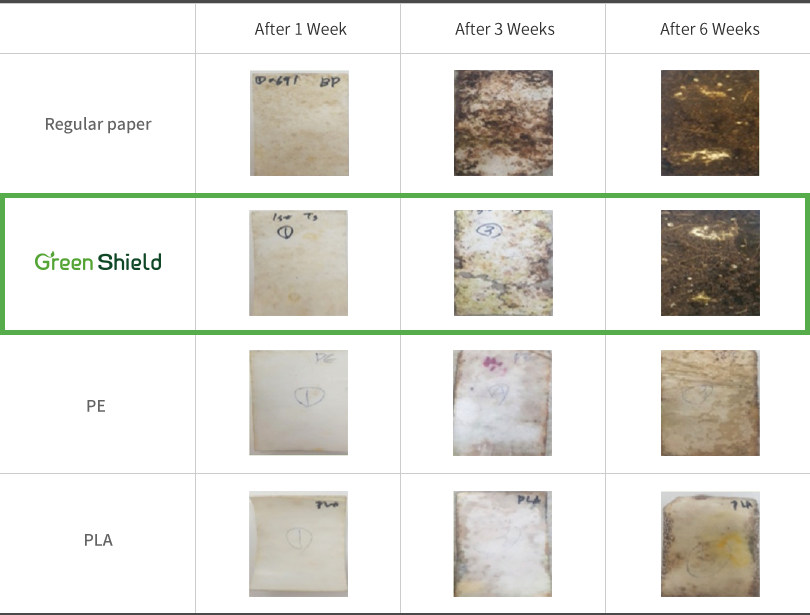

We have tested to see if Hankuk Paper’s Green Shield is really decomposable, we buried and observed it for 6 weeks, a longside regular paper

1) , and paper with regular Barrier coating (PE, PLA

2)) which is used for food packaging material etc.

As a result we were able to visually confirm that Green Shield decomposed in the ground after 6 weeks around the same degree as regular paper.

- 1) Regular paper: Possible for recycling and 100% natural decomposition in the ground

- 2) PLA: Eco-friendly resin made from raw materials of corn starch

- * This test is data from an internal laboratory conducted with culture soil under certain conditions.

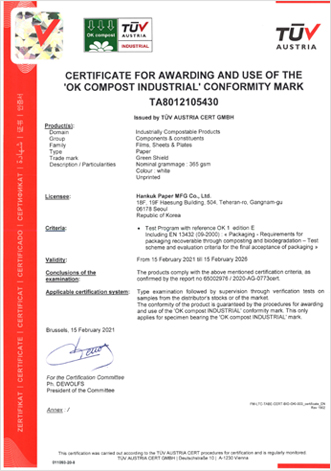

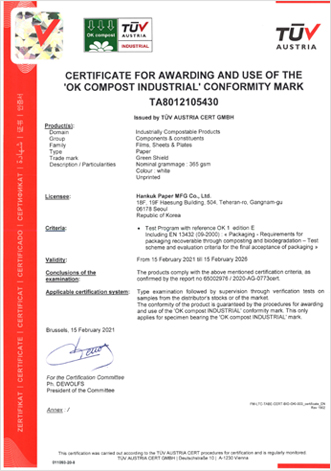

- * Acquisition of ’OK Compost Industrial’, a biodegradable certification by an external certifying institution

Green Shield, recognized for its biodegradability that is beneficial to nature

Hankuk Paper’s Green Shield has undergone the biodegradability test at ‘TUV Austria’, a European testing certification institution, and has acquired the ‘OK Compost Industrial’ by passing all hazardous substance concentration measurements, biodegradability, composting, and compost toxicity tests.

Green Shield’s ‘OK Compost Industrial’ Certificate

Green Shield’s ‘OK Compost Industrial’ Certificate

(Certified for biodegradability by TUV AUSTRIA)

-

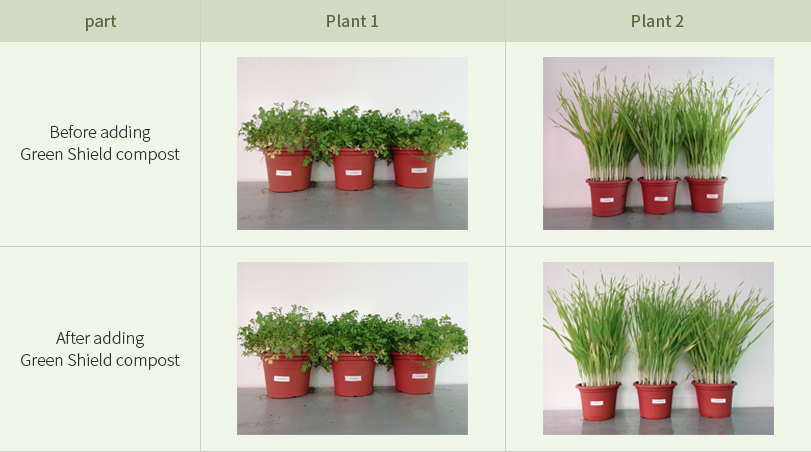

- 1) Composting test

- Green Shield decomposed by more than 90% from composting test done by TUV Austria, a figure that enables it to be used as compost.

-

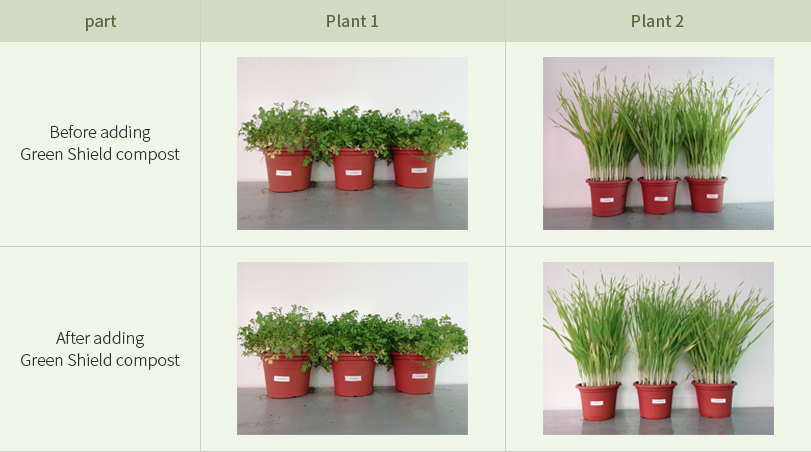

- 2) Green Shield’s compost toxicity test

- Green Shield compost created in Test No. 1 was utilized to conduct a test on the toxicity impact on plants.

As a result, it was confirmed that plants grew more than 90% compared to before using Green Shield

compost.

It can be decomposed

Is  really “recyclable”?

really “recyclable”?

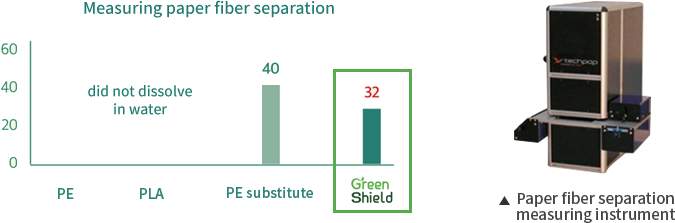

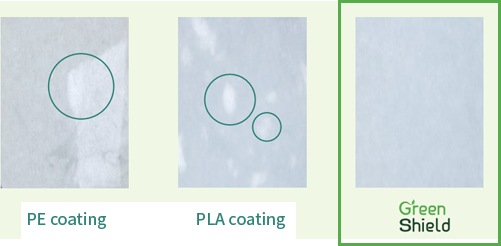

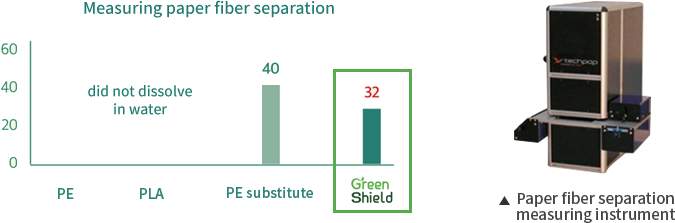

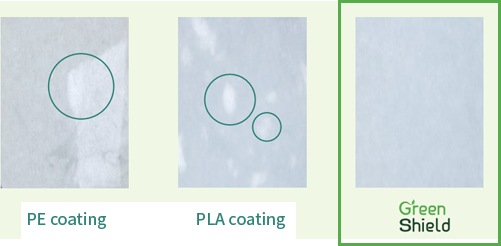

In order to measure the most basic condition for determining whether the paper is recyclable - "whether the paper gets loosened in water" – we re-created paper with Hankuk Paper’s “Green Shield” and paper with general Barrier Coating (PE, PLA) used as food packaging materials through the same process as the normal paper manufacturing method.

As a result, Hankuk Paper’s Green Shield was found to be reusable as a paper material without the need for a separate film removal process.

* Impurity removal rate during pulping process : < 3% for Green Shield (According to Kangwon National University CIPST and Canada FP Innovation Test results)

Experimental Process

- Paper fiber separation: Dispersion degree of paper fiber

Result

- Measuring paper fiber separation

- Paper with regular Barrier Coating (PE, PLA) could not be measured because it did not dissolve in water,

while, Green Shield, the number is measured as 32, confirming that it is recyclable

as an excellent quality paper.

-

- 1) Ordinary paper, the paper fiber separation value is measured to be about 30-60.

- 2) The lower the value, the better the paper dispersion of recycled paper.

- Paper Dispersion Image Analysis Results

Green Shield has been recognized for its outstanding recyclability

Hankuk Paper’s Green Shield went through a repulpability test conducted by Underwriters Laboratories (UL), a US-based organization responsible for safety standards development and certifications. Green Shield obtained the “UL ECVP 2485” rating for its outstanding recyclability, proven to show less than 4% of the paper dissociated in water.

* UL ECVP 2485 : Validation achieved for recyclability which from authenticating feasible specs for products claimed to be environmentally friendly.

It is 100% recyclable.

Good packaging material  ,

,

is it really an ‘eco-friendly’ product?

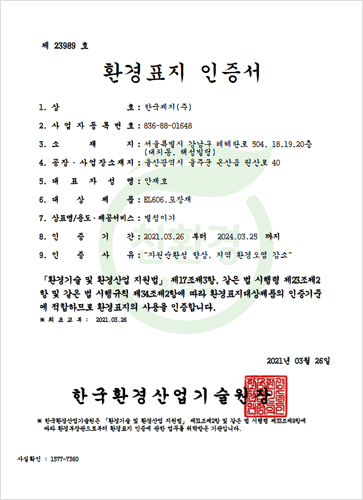

Good packaging material Green Shield which recognized for both its biodegradability and recyclability acquired the ‘Environment Mark’ Certificate in recognition of its outstanding environmental aspects through the entire process from production to disposal.

* Environment Mark Certificate : Certification system supervised by the Ministry of Environment and is assigned to eco-friendly products that can reduce energy and resource consumption while minimizing the pollutant production

Environment Mark Certificate acquired by Green Shield

Environment Mark Certificate acquired by Green Shield

It’s eco-friendly, FACT

Can  be used as a food packaging material?

be used as a food packaging material?

Q1. Is it suitable for food packaging material?

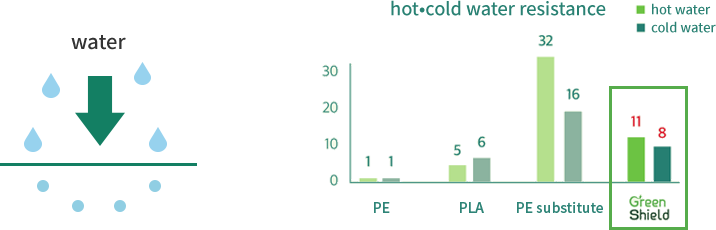

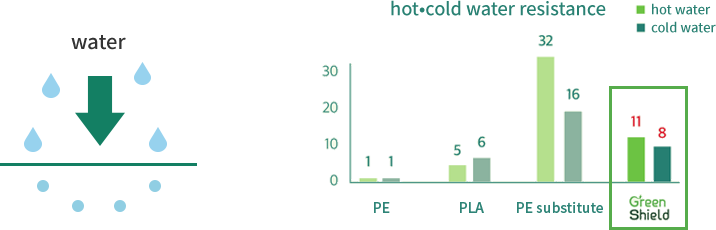

To determine whether Hankuk Paper’s Green Shield is suitable for food packaging material, the following experiment was conducted to see how much it can withstand water and oil.

The results showed that the Green Shield has water resistance

1) and grease resistance

2) at the level of a standard PE or PLA coated paper cups or food containers.

- 1) Water resistance: Property that does not get wet or soaked when it comes in contact with water

- 2) Grease resistance: Property that does not get wet or soaked when it comes in contact with grease

Water Resistance Experiment

Measuring the amount of water seeping in after contacting the coated surface for a certain period of time

to find out whether it can withstand the moisture and wetness of the food.

As a result, Hankuk Paper’s Green Shield measures at 11 gsm in hot water (90 ~ 95 ℃) and at 8 gsm in cold water (0 ~ 4 ℃), proving that it can be used as a packaging container.

- The lower the value, the better the water resistance; it can be used as a paper cup, if it has a level of 30 gsm or less

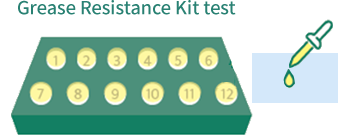

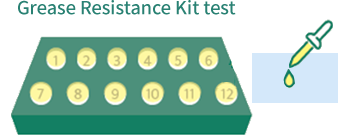

Grease Resistance Experiment

Grease Resistance Kit-TestNote) is conducted to check whether it can withstand oiliness of food

Results showed that Hankuk Paper’s Green Shield passed the 12th test in the same way as ordinary Barrier Coated (PE) paper, thus confirming that it can be used as a packaging container

- Grease Resistance Kit Test

- - Test method by dropping 12 oils with different paper

permeability in sequence

- - The higher the number, the higher the permeability

- - In the case of ordinary paper, it is all absorbed

in the first drop of oil.

Q2.Is it safe for food packaging material?

Hankuk Paper’s Green Shield complies with the <Packaging Standards of Instruments and Containers> provided by the Ministry of Food and Drug Safety.

KCL and SGS have conducted testing to check whether it produces harmful materials and has confirmed that it is harmless to humans.

It is safe for food packaging material.

Is  good in usability?

good in usability?

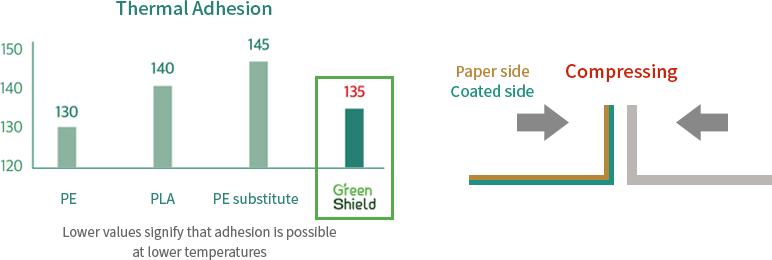

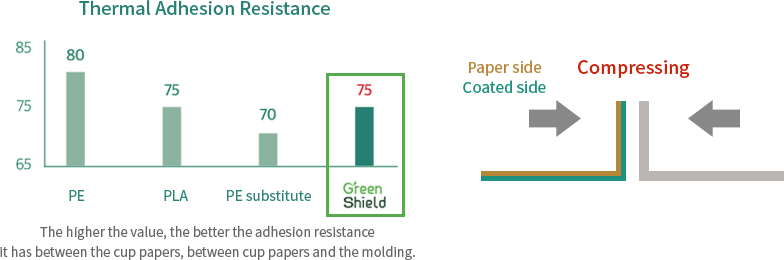

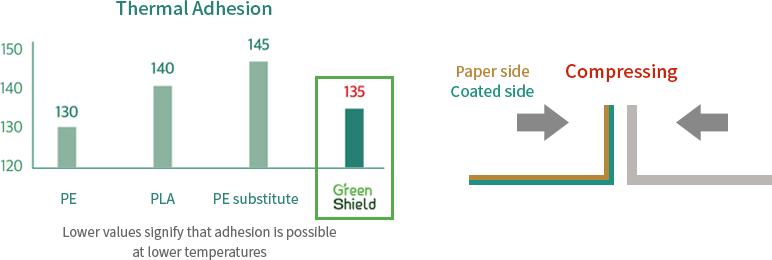

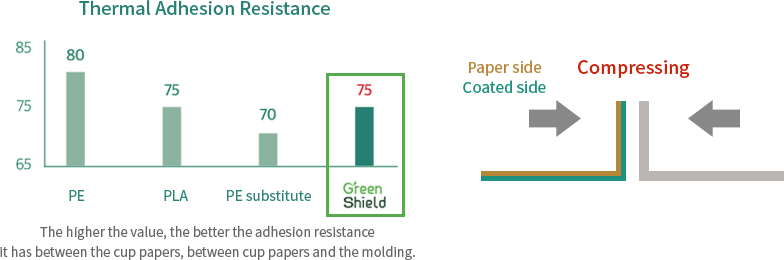

To check if Hankuk Paper’s Green Shield has good usability when processed as packaging materials, we conducted experiments on adhesive ability (thermal adhesion) and tearing (thermal adhesion resistance) according to temperature as follows.

Thermal Adhesion Test (Evaluating Adhesive Ability)

Evaluating the superiority of the adhesive ability by measuring the minimum temperature at which the adhesive coating surface is completely torn apart by incrementally raising the temperature under certain conditionsNote) of controlling pressure and time.

- pressure : 100kPa, time : 1sec

Thermal Adhesion Resistance Test (Evaluating Ability for Post-Processed Usability)

Evaluating whether the heat in post-processing work can be maintained by measuring the maximum temperature at which the adhered coating surface does not tear apart by raising the temperature at 5 ° C intervals under specific conditionsNote) of controlling pressure and time.

- pressure : 100kPa, time : 5sec

It has outstanding usability.

Let’s learn about the special processes that complete

Green Shield complemented disadvantages of paper that is weak against water and oil.

let us look at the special processes of Green Shield that are different from regular paper.

-

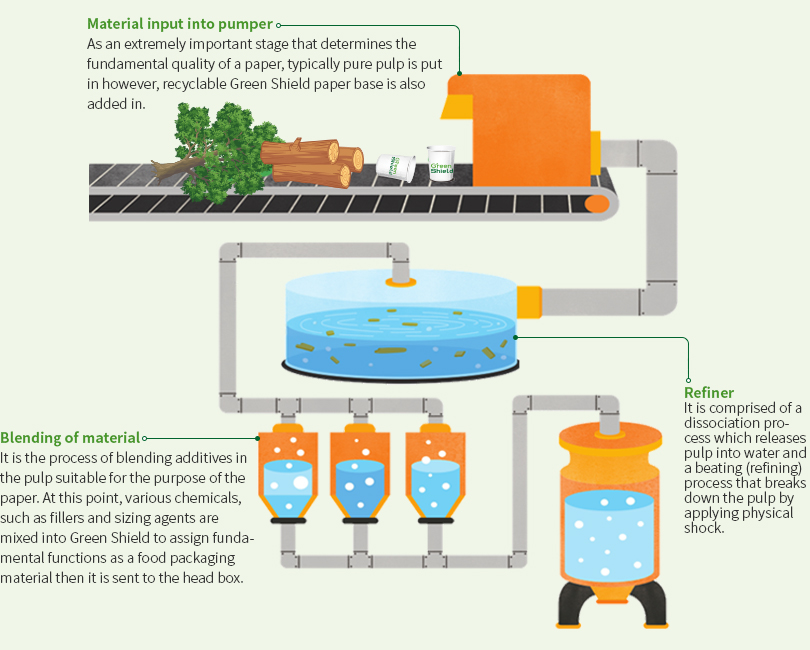

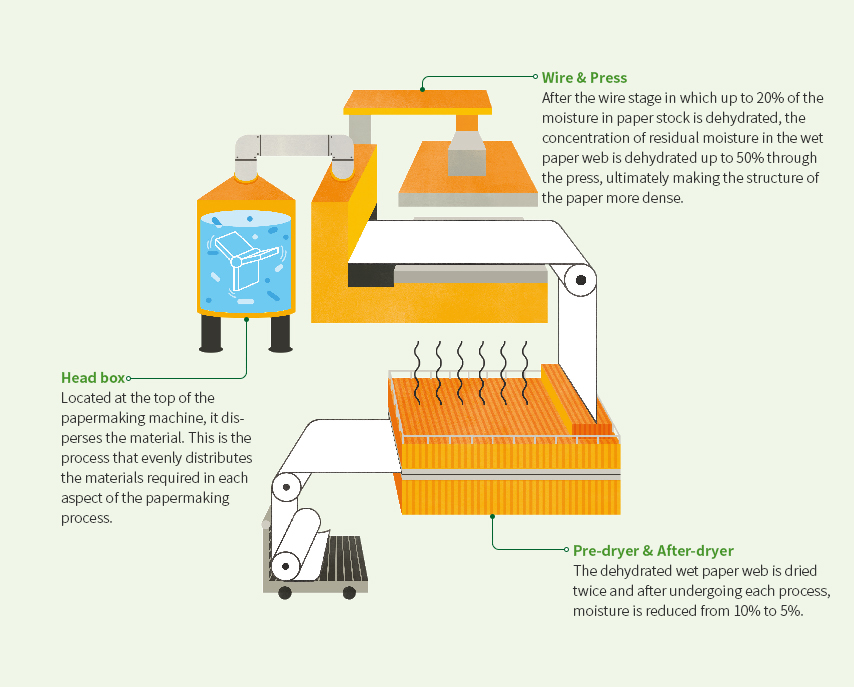

Stock preparation : Process that enables Green Shield to achieve its fundamental function as a food

packaging material

-

Papermaking process : Process that enables Green Shield to be crafted into the form of general paper

-

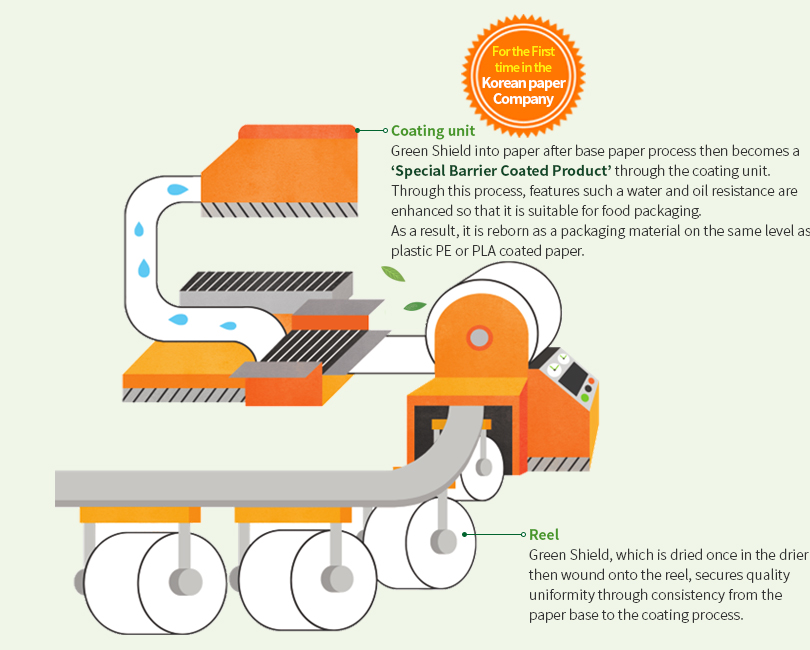

Coating process : Process where special Barrier coating occurs.

-

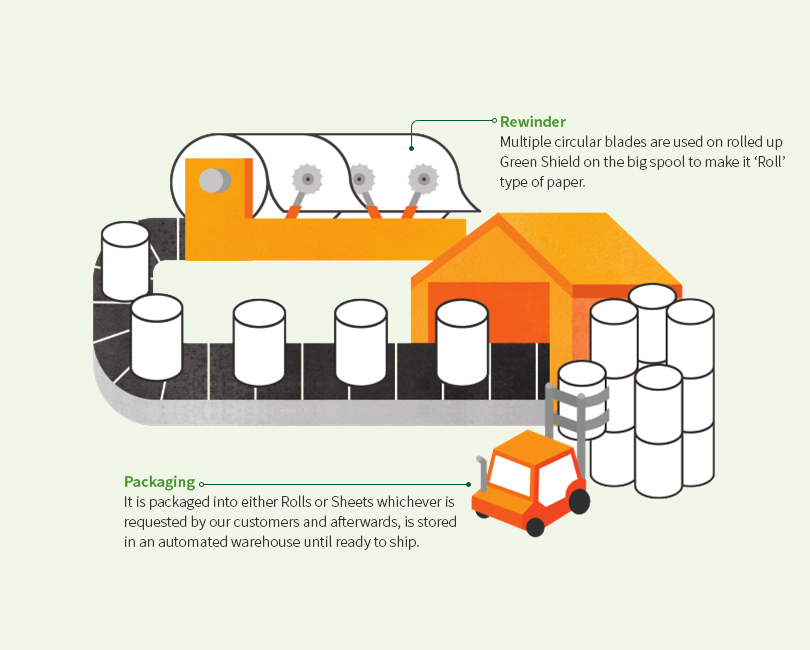

Finishing process : Process of finished Green Shield is packaged and shipped

'Green Shield Today’, Daily Record of

Biodegradability Experiment

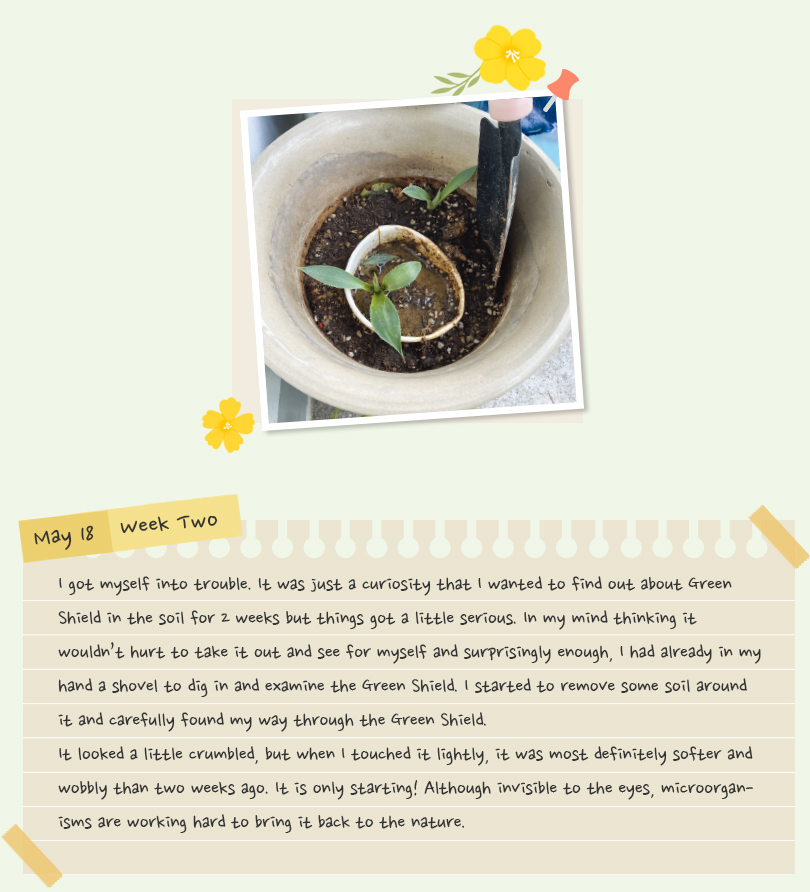

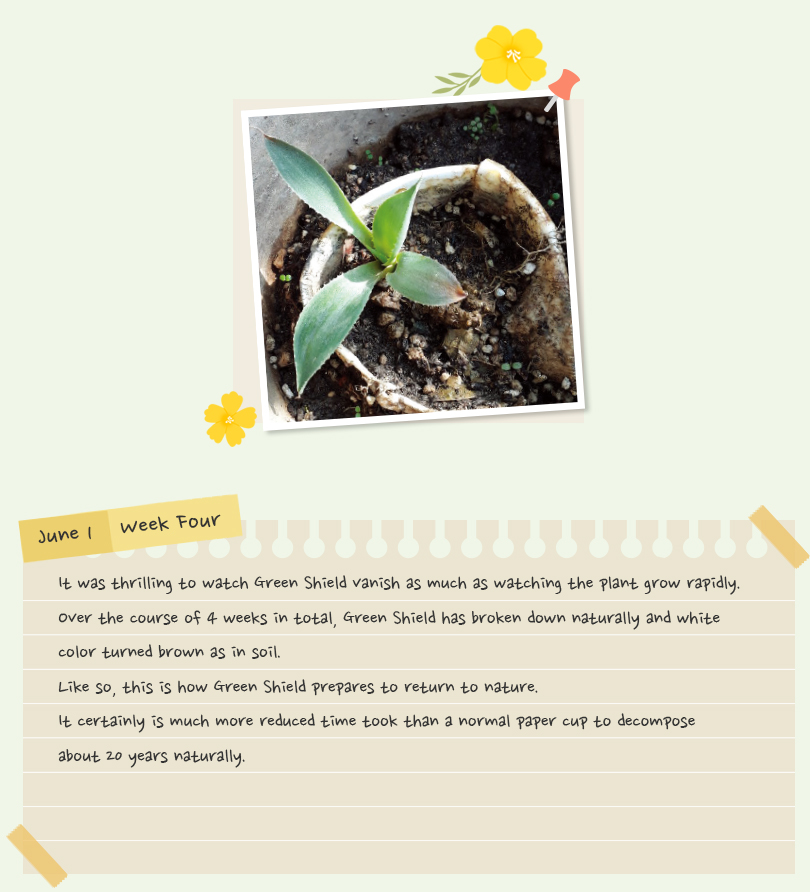

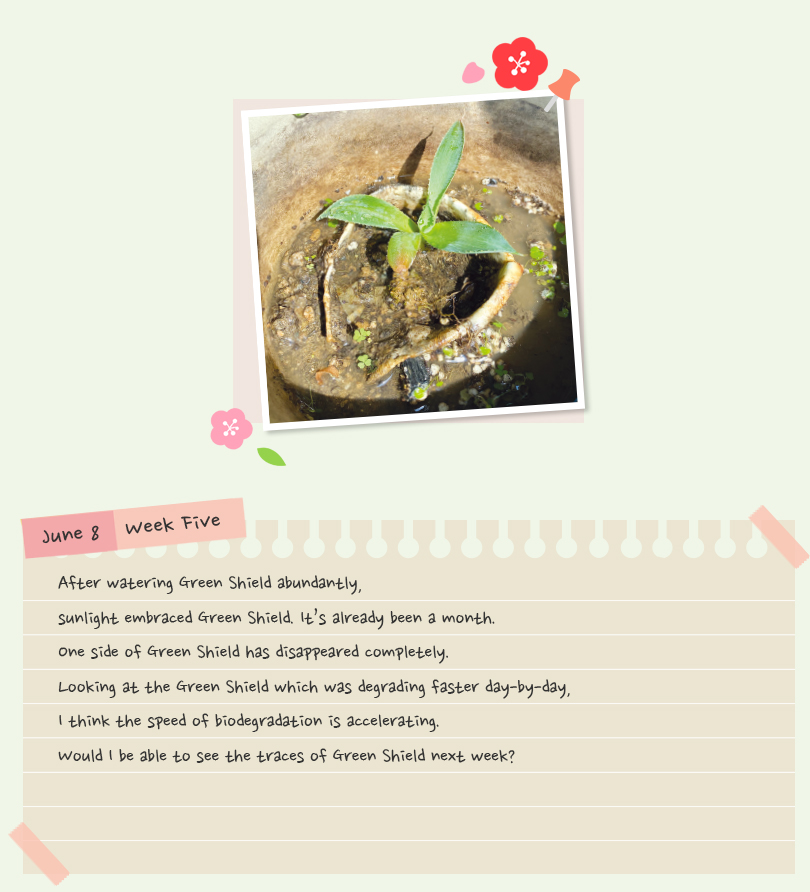

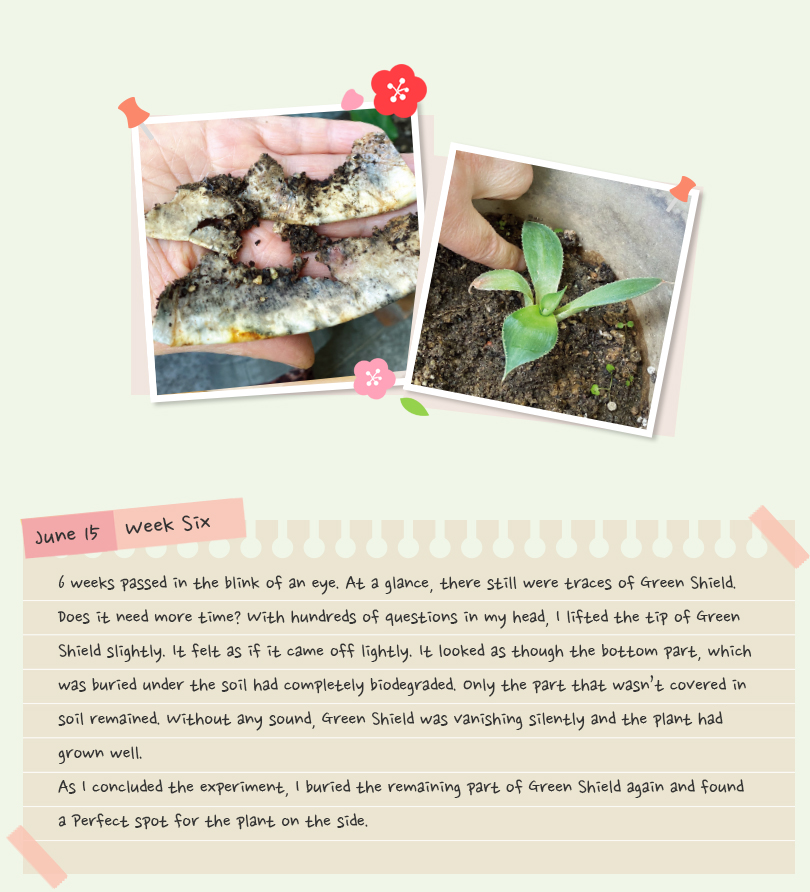

Green Shield, being eco-friendly Barrier Coating is said to be biodegradable, Is it really possible?

This biodegradable process was personally observed everyday for 6 consecutive weeks and ob-

servations were recorded on the experiment daily record.

Experiment conducted by: Hong, Mi Jeong, teacher at Pungkwang Elementary School