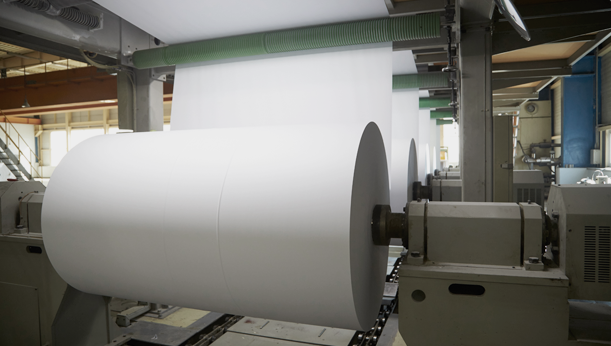

When manufacturing paper, a large amount of

steam is used to remove the moisture on the paper.

The steam needed for this process is produced using heavy oil that is fossil fuel and when the fossil fuel is burned, it generates greenhouse gases such as CO₂ (Carbon Dioxide). With continuous researches and efforts reduce the Greenhouse Gas emissions, Hankuk Paper was able to recycle the excess steam (Waste Steam) from other nearby companies in Onsan Factory and avoid using Boilers. We have fulfilled our dream of being the first ‘Chimneyless paper factory’ in Korea.